Deep Dive: How Smart Hot Water Tackles Legionella

Legionella is a serious risk in hot water systems, especially when water sits at lukewarm temperatures for too long. In this blog, our CEO Peter Armstrong explains how Mixergy’s unique design and smart controls work together to help prevent bacterial growth, keeping hot water safe, efficient, and future-ready.

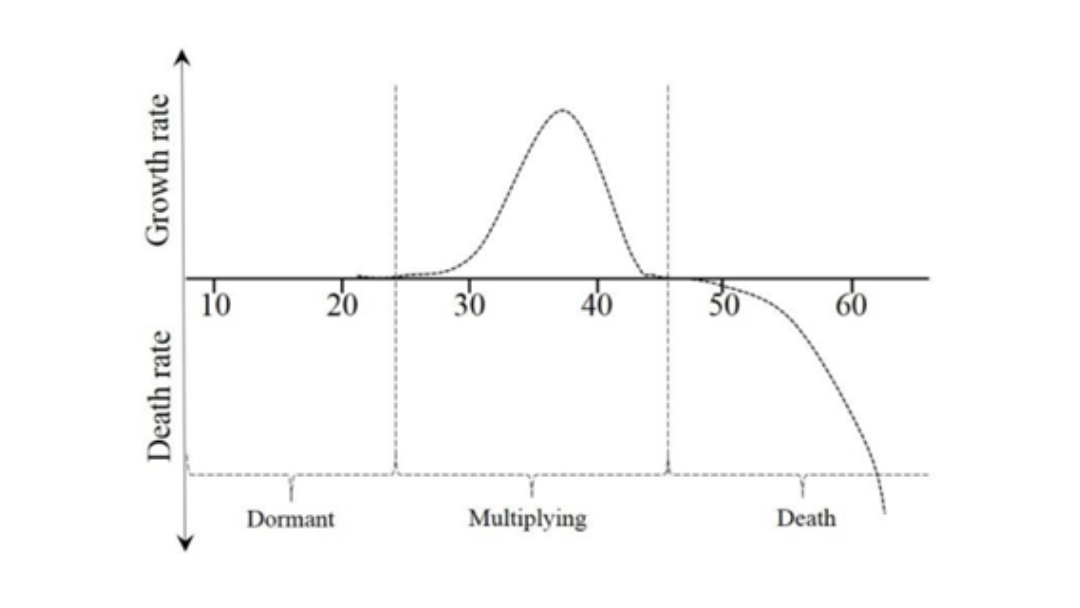

Legionella is a fastidious bacterium which grows slowly in domestic hot water systems. If someone is exposed to a pathogenic dose of legionella, a form of pneumonia (called legionnaires disease) can result. The following graph illustrates the relationship between growth rate (positive or negative) and the prevailing temperature (in degrees Celsius):

Figure 1 Relationship between growth/death rate and prevailing temperature for legionella bacteria

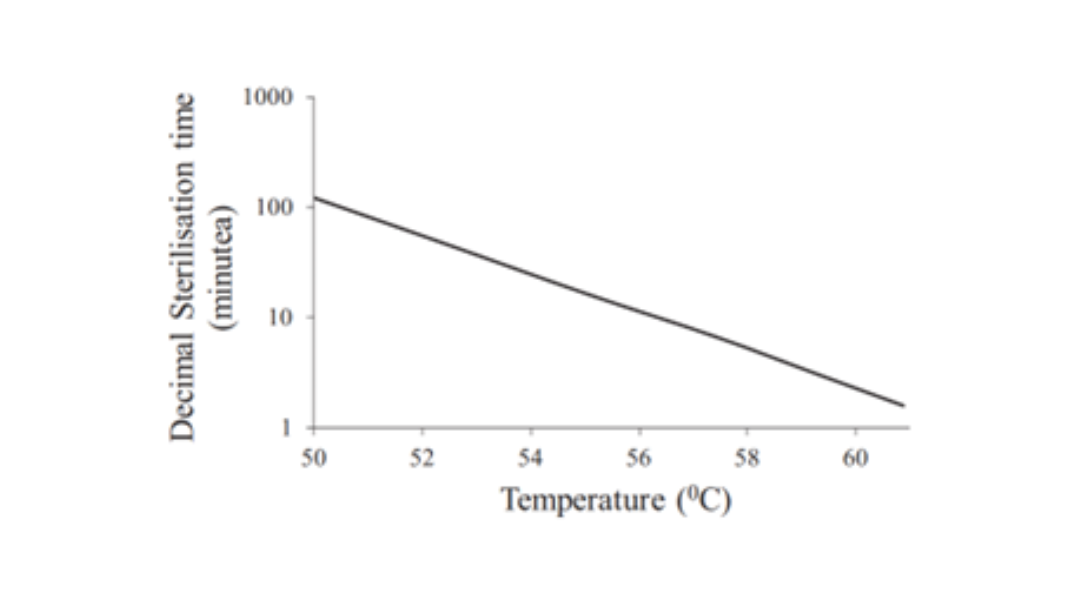

Below 20 ℃ , legionella is dormant. It’s growth rate peaks around 37 ℃ and stops around 49℃ dying off from 50℃ and beyond. The following graph shows the ‘decimal sterilisation time’, that is the time it takes for 90% of a population of legionella bacteria to die off when exposed to temperatures above 50℃:

Figure 2 Relationship between rate of sterilisation and temperature for legionella bacteria above 50℃

The primary risk factor associated with legionella is inhalation of bacterium with shower heads being a particular risk.

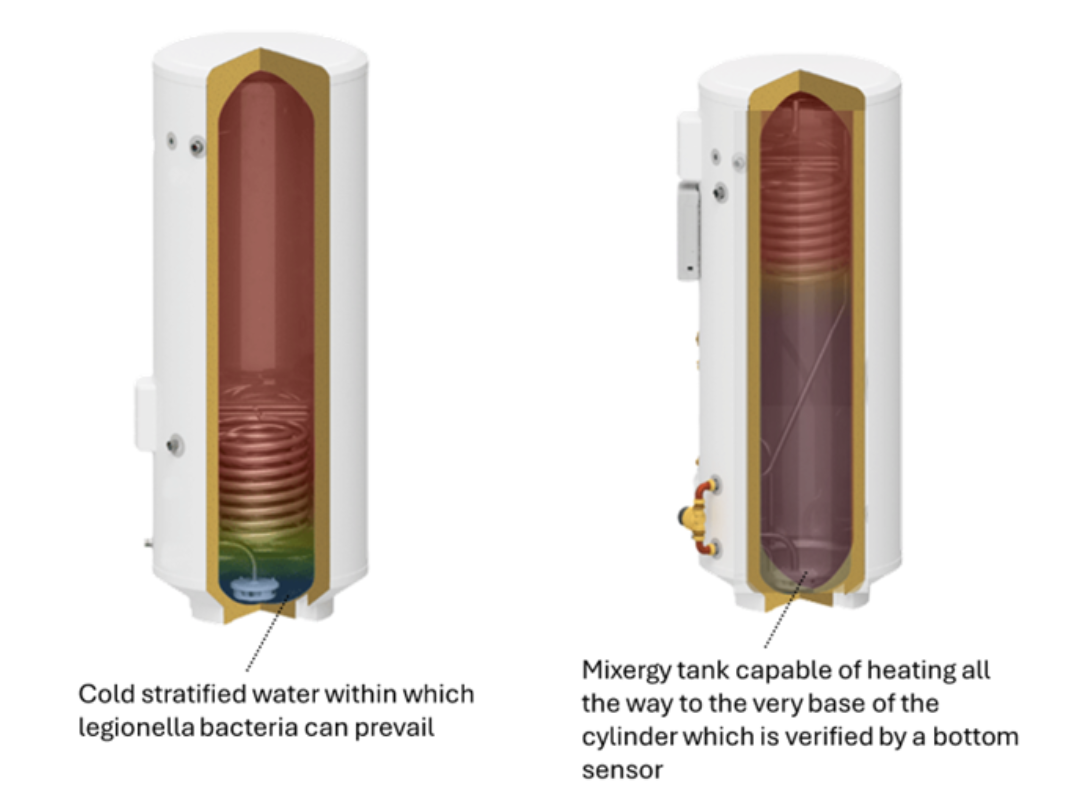

Hot water cylinders present a risk due to the fact that lukewarm temperatures, which are hospitable to legionella (and other bacterium), can prevail for extended periods of time. This can be down to a combination of control and design. The challenge is that when a hot water cylinder is heated, there is typically a portion of water beneath the immersion element or coil which remains chronically unsterilised due to the fact that heat cannot permeate down below the lowest point of any heating device. This is because water has a very low thermal conductivity (close to plastic).

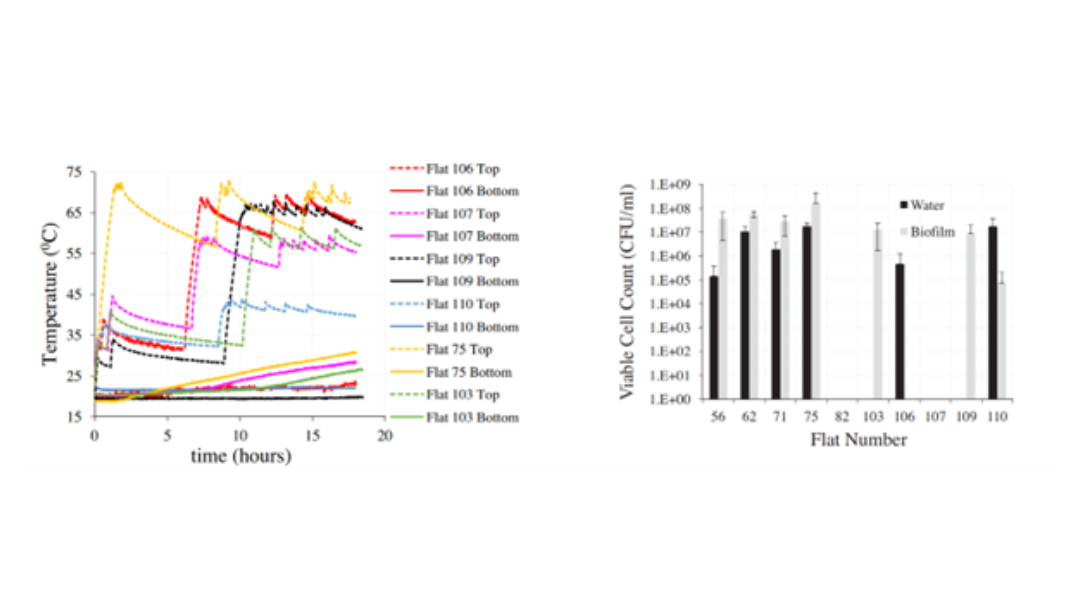

The following graph shows data from electric hot water cylinders which were heated according to an Economy 7 timing arrangement. The cylinders were in operation within a block of student flats and subsequently found to have high levels of bacteria growing at the bottom of the them.

Figure 4 Electric hot water tank temperatures [top and bottom] across a number of student flats (left) and microbial counts (right)

The base of the cylinder is a high risk area due to the large surface area combined with the tendency for scale and other waterborne debris to build up over time providing an ideal substrate for bacterial growth. When water samples were taken from the top of the cylinder, there was no bacteria present owing to the high temperatures that had been reached. The risk in conventional cylinders arises if they run out of hot water, exposing the hot water system to lukewarm/cold unsanitary hot water which has been incubated over a long time in the base of the cylinder. Mixergy addressed this first problem by design through application of our ‘top-up topology’.

When a Mixergy cylinder heats, a pump draws cold water from the very base of the cylinder and to balance thermal energy admitted to the water by a coil or heating element at the top. Every two weeks, a ‘sterilisation cycle’ is applied wherein hot water is driven all the way to the very base of the cylinder. This temperature level is verified by Mixergy’s thermocline sensor which has a temperature reference right at the bottom of the cylinder to inform its control system that sterilising temperatures have been attained.

Figure 5 Illustration of a conventional tank (left) which is incapable of sterilising the entire content of the cylinder against the Mixergy cylinder (right) which draws hot water to the very base of the cylinder through application of its top-up topology to ensure that the whole internal surface of the tank attains a sterilising temperature >50℃ at least once every two weeks

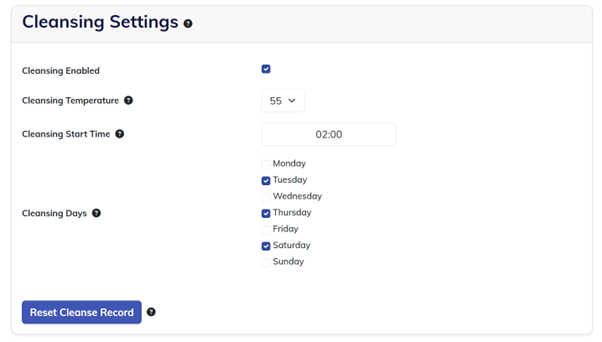

In addition to this design measure, Mixergy also adds a sterilisation control measure wherein every two weeks, a legionella sterilisation cycle is applied. The software allows users to apply their own setting, by default the system targets a 55℃ which persists >30 minutes to satisfy the sterilisation curve shown in Figure 2. Figure 6 shows Mixergy io the web interface through which users can define their own sterilisation settings:

Figure 6 Sterilisation settings applied through Mixergy user portal

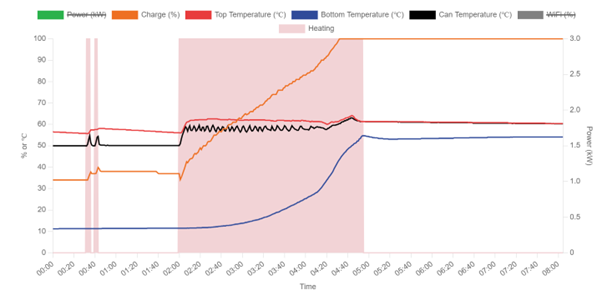

Figure 7 shows data from a Mixergy cylinder in the field undergoing a sterilisation cycle, in this instance, a temperature at the very bottom of the tank >50oC persisted for over 2 hours, well in excess of the time required according to the sterilisation curve shown on Figure 2:

Figure 7 A Mixergy tank undergoing an automatic sterilisation cycle

Our software will also track whether the cylinder has been incidentally sterilised due to a scheduled heating event, boost or surplus renewable energy (typically from roof-top solar PV) which has fully heated the whole volume of water.

Book a Free Consultation

Book a meeting with Peter McBride, Specification Director at Mixergy, to discuss your project. We’ll look at EPC / SAP compliance, the decarbonisation journey, and determine the right solution for you.