Is it time we got smarter about legionella?

Tom Oldfield

Legionnaires’ disease is a type of pneumonia, contracted by inhaling airborne water droplets that can escape from air conditioning units, hot tubs, or hot water storage. While uncommon, it can be very serious. This is why it’s a key health and safety concern for owners of conventional water cylinders, social housing developments, and those living in older homes. In this article, Tom Oldfield explains how the Mixergy cylinder prevents the conditions under which legionella develops.

Traditionally, a cylinder has either a coil connected to a boiler or an immersion heater in the bottom to create hot water through convection. A heat pump cylinder has a larger coil that goes from the top to the bottom as it needs more surface area to heat water due to typically lower flow temperatures. Although some heat pumps now give higher flow temperatures. Water is great at convection and we get lots of hot water above the immersion heater/coil. But water is a very poor conductor, leaving a grey area of water below the heat source that doesn’t get pasteurised for legionella.

How can 100% of the hot water cylinder be pasteurised for water hygiene policies?

This is where we can utilise diffuser technology and smart internet-connected technology (IoT) found inside the Mixergy cylinder.

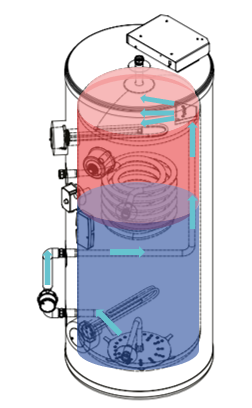

By placing the heat source at the top of the cylinder and a temperature strip covering the full height of the cylinder, the Mixergy cylinder can heat water five times faster than a traditional cylinder and monitor the temperature at every inch of the cylinder.

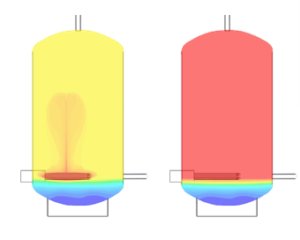

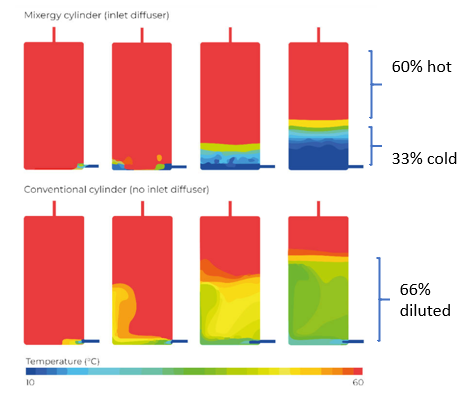

By adding a diffuser to the cold water inlet, the cold water entering the cylinder is atomised to stop hot water stirring and protect the thermocline. Think of the thermocline as a great big rubber disk that separates the hot water from the cold, except the thermocline is actually made up of water that becomes a conductor. On a traditional hot water cylinder for every litre of hot water taken out at the top, one litre of cold water is added at the bottom. The cold inlet water then starts to stir the hot water and dilute the temperature of the remaining hot water. This reduces the amount of usable hot water and prolongs the legionella pasteurisation cycle.

Water can be heated five times faster in the Mixergy cylinder because the heat source is located at the top.

By using a variable-speed pump to siphon cold water from the bottom of the cylinder and passing it through another diffuser at the top of the cylinder, the atomised cold water equalises temperature with hot water, and the volume of hot water pushes down the cylinder. This process allows the Mixergy cylinder to pasteurise 100% of the hot water.

The IoT and Machine Learning built into a Mixergy cylinder allows Facilities Managers to virtualise their fleet of hot water cylinders and create a digital dashboard to monitor hot water for their water hygiene policies. Hot water cylinders can be monitored remotely to make sure no hot water is scolding, and, through the temperature strip that runs the full height of a Mixergy cylinder, a digital record is created to prove that 100% of the cylinder has been pasteurised for legionella.

Contact us if you’d like to find out more about how smart hot water can influence future hygiene policies.